Industrializing refurbishment, worldwide.

We design, install and operate premium refurbishment workshops — processes, ERP, training and scale-up. From the first screw to executive KPIs, we deliver a system that performs. Join us to integrate repair to your workflow.

Full setup: layout, tooling, SOPs, ERP, training, pilot runs. Quickly generate up to 30× more value by fully integrating repair into your operations.

Industrial-grade quality with end-to-end traceability, powered by advanced battery diagnostics and specialized tools.

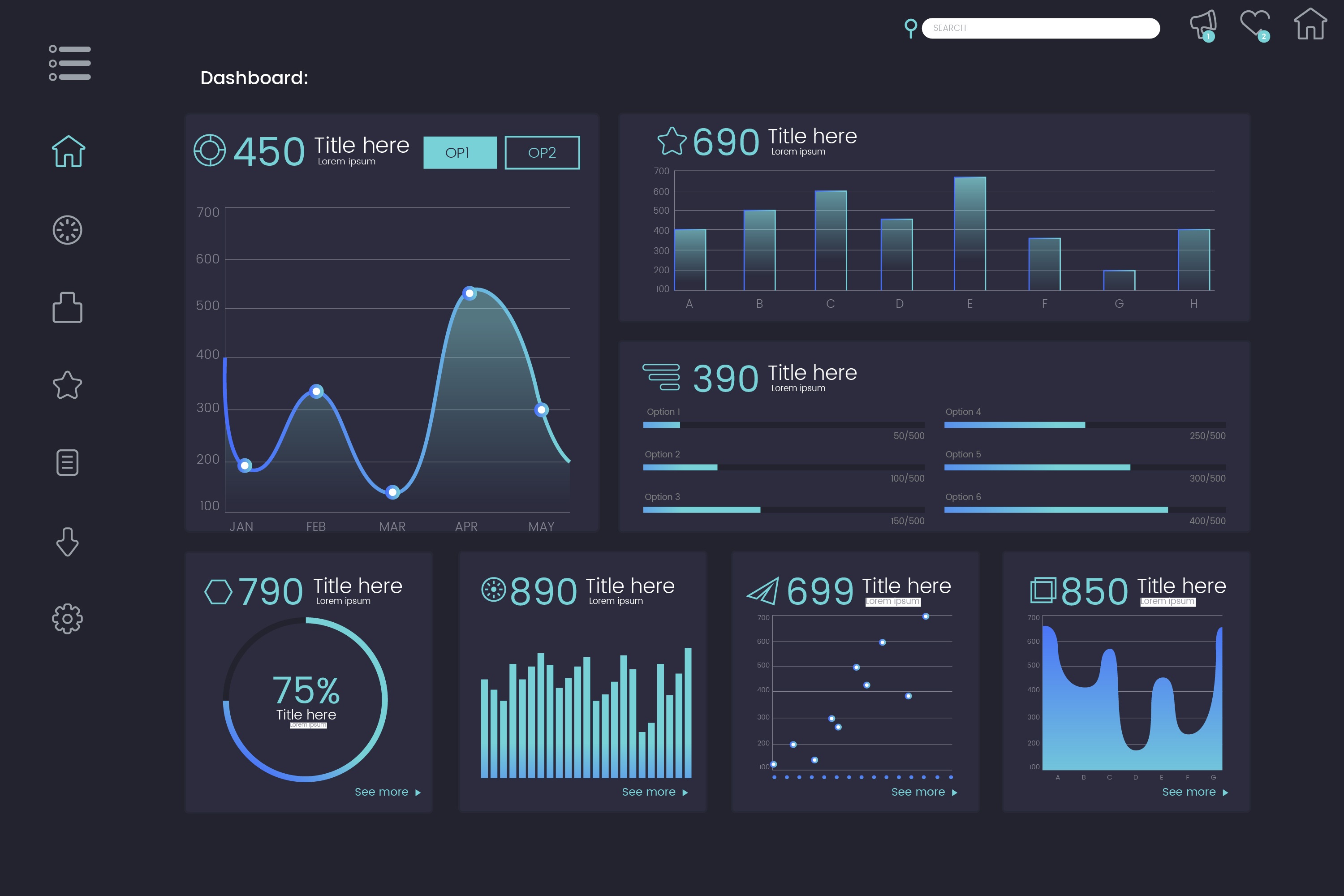

Live KPIs, circular metrics, AI-powered and fully documented processes and methods. Integrating repair has never been that simple.

Turnkey offer built to scale

One partner to go from zero to a high-performing site:

- Standardize workshop layouts and furniture for optimal performance.

- Lean production flows, 5S, ESD safety, and ergonomic workstations.

- Scalable capacity — from a single-site facility to a multi-site network.

- Comprehensive SOPs and processes to enhance quality and productivity.

- Wipe and test certificates compliant with EU and US standards.

- Internal audits and continuous improvement cycles.

- World-class partnerships with premium tool suppliers.

- Custom ERP system for repair workshops covering production, sales, and inventory.

- Role-based dashboards for operations, finance, and quality management.

- Continuous improvement driven by feedback from multiple workshops worldwide and R&D transfer.

- Access to new diagnostic methods and advanced battery technologies.

- Setting the standard for the global refurbishment industry.

We build on proven execution

REAV leverages an operations ecosystem that already delivers at industrial grade: a group DNA focused on repair, a live pilot workshop, and a training backbone recognized in the field.

Our Ambition

Deploy standardized, audit-ready workshops ensuring consistent, high-quality standards everywhere. Fully AI-powered, documented methods and processes integrated into a specialized ERP.

Design scalable capacity to absorb fluctuations in volume and device mix. Multi-site orchestration, demand smoothing, buffer strategies, and supplier qualification ensure resilience and protect margins.

Transparent dashboards enable data-driven executive decisions for easy workshop optimization. Automated ESG impact analytics ensure measurable performance, accountability, and trust.

Deployment method

- Diagnosis & Scoping — objectives, volumes, constraints, business case.

- Design & Sourcing — layout, stations, tooling, ERP, plan.

- Build & Training — install, ERP setup, SOPs, teams onboarding, training.

- Pilot & Ramp-up — improvement loops, quality and flow secured.

- Steady state — method and R&D transfer, coaching, audit.

- 📈 Generate up to 30× more value by fully integrating repair into your operations.

- 🧰 We handle it all. From setup and equipment to training and performance monitoring — we’ve got you covered.

- 🧾 Repair made simple, with our turnkey solution combining custom ERP, training, and proven processes.

- 🌍 Scale globally, expanding your repair capacity anywhere devices need to be fixed — without sacrificing quality.

Choose the model that fits your strategy

Operate under the REAV brand with a licensed playbook: standards, ERP, supply, training and audits. You keep ownership, we enforce quality and performance.

- Brand & standards license

- On-site launch team

- Performance reviews & monitoring

We co-invest and co-govern a local entity to accelerate market entry or scale. Aligned incentives on throughput, quality and profitability.

- Shared capex & governance

- Integrated leadership & reporting

- Multi-year growth roadmap

Keep your brand and operations while leveraging our methods. We design, implement and coach your teams to reach industrial-grade performance, fast.

- Blueprint, SOPs, ERP setup

- Ramp-up program & coaching

- Audits and continuous improvement

Build your refurbishment capability with REAV

Tell us about your project — we’ll come back with a sharp plan.